Research & Development

Integration of robotics and the seismic measurement technology

Development of an earthquake motion simulator to contribute to global earthquake disaster prevention

Published: Nov. 30, 2020

Published: Nov. 30, 2020

Our Joint research with a University began with a simple idea

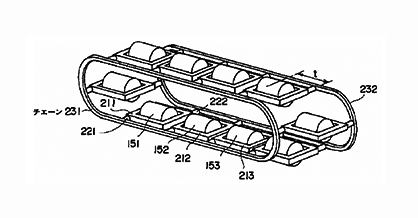

Hakusan Corporation was founded in 1958 as a slitter manufacturer. Today, in addition to our disaster prevention system business, the mechano-system business continues to be a mainstay of the company's earnings. The company has always engaged in actively incorporating technologies and knowledge from several fields, including robotics, to increase the product value of slitters, a type of production equipment used in factories. The portable earthquake motion simulator called “Jishin-The-Vuton” is a product of this endeavor. In 2007, while discussing the utilization of the compact crawler-type omnidirectional moving mechanism (Vuton) invented by Professor Shigeo Hirose of the Department of Mechanical and Aerospace Engineering at the Tokyo Institute of Technology (currently the director of the HERO Lab.), the idea of "a device that can accurately reproduce earthquake motion for a realistic experience" was conceived. The Vuton has a ground contact area larger than that of wheeled vehicles and can achieve a high propulsive force and load bearing capacity, in addition to the ability of running freely in any direction (east, west, south, and north) using servo control.

In 2008, we began a joint research project with the Tokyo Institute of Technology to develop Vuton, which was designed to simulate realistic seismic motion with people on board.

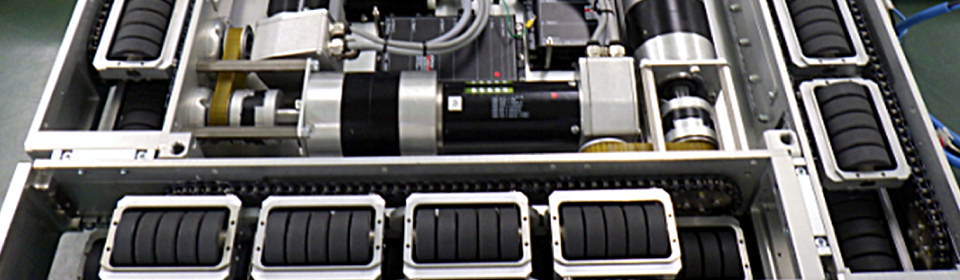

Operation of the Vuton (at that time) at the Tokyo Institute of Technology

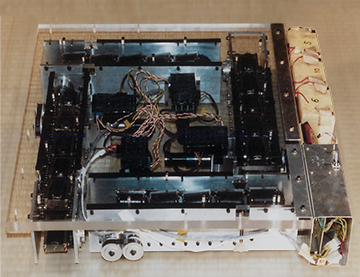

First-generation Vuton, which was

First-generation Vuton, which was

conceived at the Tokyo Institute of Technology Diagram illustrating the principle structure of a crawler

Diagram illustrating the principle structure of a crawler

As a disaster prevention system developer,

we produce high-quality earthquake simulators.

That is our commitment to society.

Our company, who is involved in earthquake observation, designed a translation mechanism considering the following reproduction performance goals for designing an earthquake experience device.

- ・The system must be able to accurately reproduce the waveforms of earthquakes with seismic intensities of five or greater that have actually been observed.

- ・The system must be able to reproduce long-period ground motion, which is supposed to be caused by an ocean-trench-type earthquake.

- ・The system should reproduce not only geological phenomena, such as seismic motions (observation data), but also the shaking caused by the deformation of the upper floors of buildings (response simulation data), thereby simulating various cases in which citizens are actually affected.

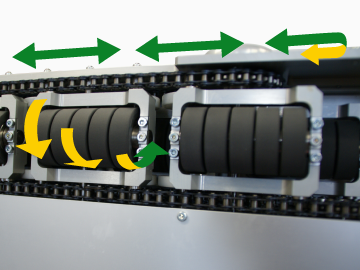

The early Vuton crawlers developed at the university were relatively slow; both the speed of travel and acceleration must be properly controlled to accurately reproduce the seismic motion.

For example, long-period ground motion is described as "shaking slowly," but the speed of the floor responses of high-rise floors with large amplitudes tends to be higher than that of ordinary earthquakes and cannot be reproduced unless high-speed translation is achieved. Additionally, to reproduce a large earthquake that can reach an intensity of seven, it is necessary to repeat acceleration and deceleration at a certain level. There exists a tradeoff in design between achieving high-speed translation and acceleration/deceleration performance while generating sufficient torque to move the crawler itself while carrying the weight of the person experiencing motion; thus, we examined the layouts of various deceleration mechanisms and confirmed the performance ranges that could be covered on a three-axis graph* (see figure below). Thereafter, we applied the machine to the area on the graph that we believed would be the most useful for an earthquake motion simulator.

Performance targets set at the beginning of development (on red line)

Invention from the perspective of machine control

The development of the Vuton control unit also required unique innovations. In the design of electric automated guided vehicles (AGVs), which are often used in industrial applications, it is sufficient to select and arrange the power supply and motor drive circuits required for motor acceleration at the start of travel and during cruising, and deceleration is simply considered as acceleration in the opposite direction. However, the acceleration generated by an earthquake motion simulator is incomparable to that of an AGV, and intense acceleration and deceleration are repeated in 0.01 s without interruption. Consequently, with repeated acceleration and deceleration, the effect of the motor current flowing backward at the moment of deceleration causes the power supply unit to fail. If the Vuton were a running vehicle, it would be equipped with brakes; however, because acceleration (deceleration) must be accurately controlled during earthquake reproduction, servo control must be used. This problem was resolved using a shunt regulator circuit and regenerative resistor in the control unit to consume excess current in the form of heat.

We considered incorporating a bank of supercapacitors (large-capacity capacitors), which began to gain popularity at the time, into the control unit to store regenerative current and reuse it during acceleration, a method used in hybrid cars and elevators. However, the cycle of charging and discharging was excessively intense, and we judged that the life of the capacitor would not be sufficient. Thus, we abandoned this idea at the development stage. Capacitors have made significant progress in recent years owing to the widespread use of electric vehicles and may eventually gain utility in Jishin-The-Vuton.

Motion of a crawler

Motion of a crawler- Intense acceleration and deceleration repetitions

Utility in the field of earthquake disaster prevention,

including raising awareness, education, and training

The control unit, which includes additional functions such as video reproduction, was designed to operate with a 100 V commercial power supply. The driving motors of Jishin-The-Vuton are four units rated at 400 W, which are instantaneously driven at hundred percent of their rated output. However, Jishin-The-Vuton is operated in conference rooms in offices and lobbies of condominiums, where power supply capacity is limited; thus, the selection of a power supply has to be well considered.

Real observed seismic motion data (acceleration values) were filtered for translation control by speed servos, and the video content of indoor damage was edited to enable easy interpretation of the operation of an earthquake menu to select different types of experiences. Joint research was conducted with the Midorikawa Laboratory at the Tokyo Institute of Technology.

Improvements were made in response to the problems encountered when we took our prototype to various conferences and local government events before the product was commercialized. This is a good example of the following design thinking that we value: fabricate a product, deploy it in the field, and then continue improving it.

Various functions and mechanisms developed in relation to Jishin-The-Vuton

Jishin-The-Vuton 3D

The Jishin-The-Vuton model currently in the market reproduces only the horizontal (east-west, north-south) shaking of earthquakes; however, we have also been working on the development of a mechanism to reproduce vertical (up-down) shaking. Joint research was conducted with the Hirose Laboratory at the Tokyo Institute of Technology.

This mechanism uses a pneumatic cylinder to raise and lower a chair fixed to the main body of Jishin-The-Vuton and is designed to move up and down according to seismic motion data using an electro-pneumatic regulator. However, for safety reasons, we were forced to abandon this concept in the commercial product as it causes dangerous levels of strain on the neck and back of riders due to the horizontal and vertical shaking motion while being secured with a seatbelt. Additionally, we encountered several operational issues such as longer waiting times for air replenishment after each experiment, additional equipment requiring installation, and excessive noise.

Jishin-The-Vuton air

We also worked with the university on research and development to consider increasing the size of our system so that multiple people could simultaneously stand during the ride, instead of sitting. The resulting model is larger (1300 × 1300 mm) than the commercial Jishin-The-Vuton model; instead of the Vuton crawler, this mechanism uses air levitation (air bearings) to slightly raise the entire device off the floor. The device is pulled and driven by wires in four directions. We are developing a servo-type winding mechanism for real-time wire control and a control algorithm to reproduce seismic motion on a plane (Mechanical Systems Design Laboratory, Tokyo Institute of Technology, Japan). This technology is also being used in the development of new robots in our extreme environment robot laboratories.

Jishin-The-Vuton mini

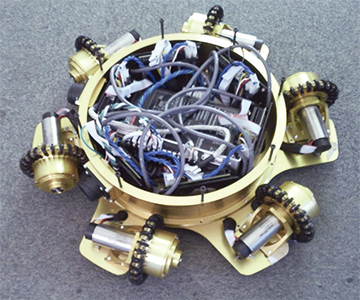

We developed a small, lightweight, circular machine with a diameter of 500 mm to reproduce shorter-period shaking compared with that in the main Jishin-The-Vuton model, which can be used for experiments based on dummy models. The traveling mechanism is a newly developed six-axis drive wheel with several aluminum mini-rollers arranged in a circle. High-torque motors (Maxon motors) and servo amplifiers are used for power and control. This prototype is capable of reproducing agile tremors at frequencies of 5 Hz and above and is currently being used to demonstrate our earthquake disaster prevention system for high-rise buildings (joint research with Kato Laboratory, Meiji University, and Professor Emeritus Hirose of the Tokyo Institute of Technology).

Research results

Conference presentations and papers

- Paper"The VUTON: High Payload High Efficiency Holonomic Omni-Directional Vehicle," Proc. of the 6th International Symposium on Robotics Research, pp. 253-260, 1993.

- Paper"Development of ‘Jishin-The-Vuton,’ The Portable Earthquake Simulator Using Omnidirectional Platform," The 27th Annual Conference of the Robotics Society of Japan, September 2009 (in Japanese).

- Paper"Development of Earthquake Experience System Using Ground Motion Simulator ‘Jishin the VUTON,’" 7CUEE, pp. 317-320, 2010.

- Paper"Development of Portable Earthquake Simulator for Enlightenment of Disaster Preparedness," Proc. of 15th World Conf. in Earthquake Engineering, 2012.

- Paper"Development of the Portable Ground Motion Simulator of an Earthquake," Proc. of IEEE/RSJ International Conference on Intelligent Robots and Systems, pp. 5339-5344, 2013.

- Paper"Conceptual Design of a Cable-Driven Parallel Mechanism for Planar Earthquake Simulation," The 21st CISM-IFToMM Symposium on Robot Design, Dynamics and Control (ROMANSY2016), Springer, pp. 403-411, 2016.

- Paper"Reproduction of Long-Period Ground Motion by Cable Driven Earthquake Simulator Based on Computed Torque Method," Proc. of the 4th International Conference on Cable-Driven Parallel Robots, Springer, pp. 415-424, 2019.

- Paper"Portable Earthquake Simulator Using Omnidirectional Wheels in Twist-Radial Configuration - High Acceleration Drive Mechanism," Proc. of the Seismological Society of Japan, vol. 19, No. 7, pp. 56-66, 2019 (in Japanese).

- Paper"Offline Reference Trajectory Shaping for a Cable-Driven Earthquake Simulator Based on a Viscoelastic Cable Model," IEEE Robotics and Automation Letters, vol. 7, no. 2, pp. 2415-2422, April 2022.

- Bulletin & Report"Earthquake Experience Device Using Omni-directional Moving Vehicle Mechanism," Journal of the Japan Society of Mechanical Engineers, vol. 114, No. 1111, pp. 448-449, 2011.

- Bulletin & Report"Earthquake Experience Education in More Diverse Places and More Diverse Styles" JAEE NEWSLETTER Vol. 2, No. December 4, 2013 (in Japanese).

- Bulletin & Report"Technology to Switch on Communication," 2016 Symposium of the Disaster Committee of the Architectural Institute of Japan, "How to Overcome Urban Earthquake Disaster with Mutual Aid and Technology,” (in Japanese).

- Bulletin & Report"Earthquake Experience VR - Let's Experience the Fear of Earthquake with VR," The 23rd Conference of Metropolitan Residents for the Promotion of Earthquake Resistance, 2019 (in Japanese).

Awards

- Invention Encouragement Award 2012 Kanto Regional Commendation for Invention

- 2013 Technology Award Japan Institute of Social Safety Science

- Japan Resilience Awards 2016 "Excellence Award"